Unloading pipes on-site:

They must be unloaded with suitable material and human resources for it to be done safely.

Follow the manufacturer's instructions for this.

The contractor must supply the most appropriate pipe unloading and handling procedure for the quality specifications of the work.

The concrete pieces can be unloaded with conventional excavation and elevation machinery, provided appropriate equipment is available, to control the unloading movements accurately. Mobile cranes are recommended for unloading pipes weighing more than 2,000 kg.

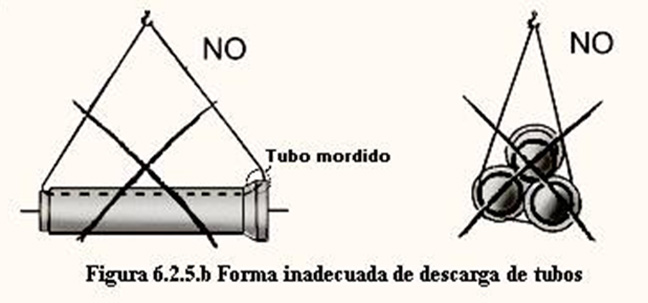

The following figure shows the tools and accessories usually used for unloading. The points of contact of these tools with the pipes must have rubber protection.

Once the pipe is suspended, until it is positioned at its storage location, the following observations must be taken into account:

a) Prevent pipes striking each other and the ground.

b) Guide the load when lifting and depositing it.

c) Operate gently.

d) Do not stand under the load.

e) Prevent the pipe resting on isolated points or on rocks.

f) After unloading, do not drag or roll the pipes.

g) Chock the pipes with suitable materials that will not damage the pipe.

h) Unload them as close as possible to where they will be installed.

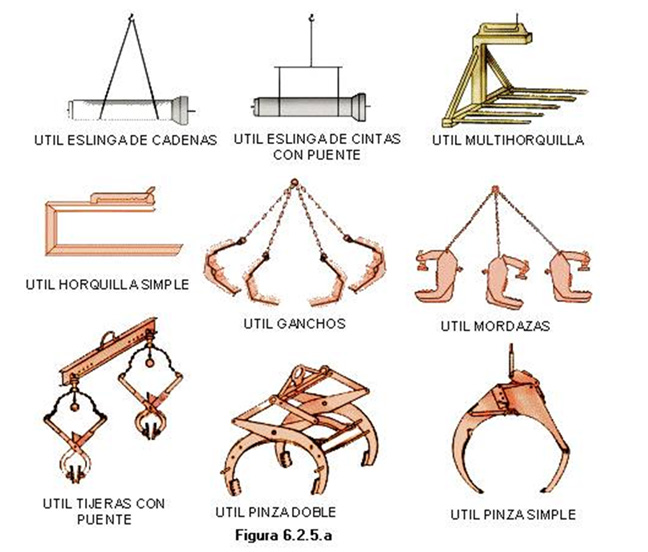

Do not handle them with devices made up of bare cables or chains in contact with the male or female ends of the pipe. If necessary, the cables and chains must have protective linings in the areas in contact with the pipe.

It is also forbidden to unload several pipes at the same time using cables or chains, except when a suitable multi-fork tool is used.

We recommend suspension using suitably covered wide bands or slings or mechanical callipers that grip the pipe along its length. If you use forks inserted into the pipe, the whole area in contact with it must be coated with wood or gum.

Coordinating the supply with the pace of the work reduces the movement of the pipes and, consequently, prevents the risk of damaging them during handling.

It is advisable to unload the pipes at the edge of the trench, whenever possible, leaving a suitable gap, to avoid later handling. Try to place them on the opposite side where material from the trench excavation is piled.

When the pipes are to be installed in a backfill area, they can be left practically in their definitive position.

PREPARING THE BASE OF THE TRENCH

The slope and the material at the base of the trench must comply with the project specifications. The material at the base of the trench must not be altered. If it is modified, the bearing capacity stipulated originally must be preserved.

When the pipeline is laid at the base of the trench, this must be adapted to the slope and specific shape of the pipe, so that full support is ensured throughout the length of the pipes.

To achieve them a uniform grade line, fill the base of the trench, preferably with loose sand, gravel or crushed stone (smaller than 20 mm), and compact it to avoid it settling differently.

If you have an inconsistent layer of earth in the base of the trench, the standard UNE-EN 1610 indicates that you must remove it and replace it with a suitable material. If you find significant volumes you must reevaluate the structural design.

This filling must be carefully it is packed in layers and the surface made uniform. If the base of the trench it is filled with sand or gravel, when the type of pipe requires it, carry out the filling and make niches for this piping.

The pipes shall not rest directly on the grade line of the trench, but rather on beds.

The specifications of these beds will depend on the soil, the dimensions of the pipes and the type of pipe used.

When low temperatures require it, it is necessary to protect the base of the trench so that the frozen layers are not under or next to the pipes.

The General Technical Specifications for Urban Wastewater Piping from the Spanish Ministry of Development classifies terrain into the three following qualities:

- Stable: Consolidated terrain, with guaranteed stability. This type of filling includes, rocky, transit, compact and similar.

- Stable: Consolidated terrain, with guaranteed stability. This type of filling includes, rocky, transit, compact and similar.

- Unstable: Terrain with possibility of localised expansion or settlement, which with suitable treatment can be corrected to meet similar specifications to stable terrain. This type of terrain includes, clay, filling and other similar materials.

- Exceptionally unstable: Terrain with a high possibility of settlement, slippage or other disturbances. This category includes mud, expansive clays, shifting ground and similar.

Consequently, with this classification and according to the specifications of the pipes, the gaskets and the terrain, the beds indicated in Table 6.3.7. are recommended. For bad terrain, and to prepare them before placing the bed, the special type of base recommended in each situation is indicated in the same table. When the terrain is very bad, the designer or site manager will study the most suitable solution in each specific case.

Table 6.3.7

We use our own and third party cookies, for the analysis of user navigation. If you continue browsing, we consider that you accept the use.

You can change the settings or get more information here.

Arriandi auzoa, 1

48215 Iurreta (Bizkaia)

Tel.: +34 94... see telephone number

Fax: +34 94... see fax

Prefabricados Alberdi - Copyright 2012 | Legal notice | Data protection | Sitemap | Cookies

Website site designed

and developed by DMacroweb